SV-T Digital Torque Driver

User manual:

- Overview

1.1.Main purpose and scope of application

The SV-T Digital Display Torque Driver is a product carefully designed for the assembly and torque detection of small torque screws in the precision manufacturing industry. End tool for tightening torque precision connections. Compared with mechanical preset screwdrivers, torque control is more precise.

1.2.Characteristics

① Torque can be read directly.

② Auto-off without operation for 10 minutes to save power.

③ Operate clockwise and counterclockwise.

④ Can freely switch three working modes of real time, highest value and preset value.

⑤ Four torque unit options (N.m, lbf.ft, lbf.in, kgf.cm).

⑥ It has the function of storing data in peak mode.

⑦ Torque direction markers and battery level display.

1.3.Specifications and models

| model | range

(N.m) |

division value (N.m) | accuracy | Hexagon shank | weight | |

| inch | mm | (kg) | ||||

| SV-T-0.5D | 0.05-0.5 | 0.0001 | ±2% | 1/4 | 6.35 | 0.4 |

| SV-T0220D | 0.2-2 | 0.001 | 1/4 | 6.35 | ||

| SV-T-4D | 0.4-4 | 0.001 | 1/4 | 6.35 | ||

| SV-T-8D | 0.8-8 | 0.001 | 1/4 | 6.35 | ||

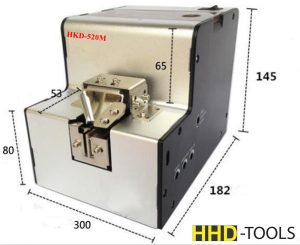

- Product structure

2.1. Appearance Diagram

2.2. Screen Diagram

- Specifications

3.1.Accuracy: two-way 2%.

3.2.The pre-warning range is 85% of the preset torque value.

3.3.Power supply: 2 AAA batteries.

3.4.Operating environment: temperature (0~40)℃, humidity ≤85%.

3.5.Storage environment: (-10~60)℃.

- User Manual

4.1. Operating manual

①Power On/Off

Power on: Press the “P/C” key to turn the screwdriver on or off. If the power supply is insufficient, it will automatically turn off; If the screwdriver does not work for 10 minutes, it will automatically turn off to save battery.

② Working mode setting

Press and hold “M” key to enter menu program, lightly press “M” key to switch to MODE option, then lightly press “△” key to select working mode. “track” is the real-time mode, “Pre.” is the preset mode and “peak” is the peak mode.

- Real-time mode

In real-time mode, the LCD displays word tracking to realize real-time monitoring of torque value. In real-time mode, LCD display shows real-time load torque value.

b.Preset mode

In the torque driver working interface, press the “△” button to display the preset, press the “△” button again to set the preset, when the preset is adjusted to desired value, press the “M” button to save and exit. When the lock is in preset mode, when the locking torque reaches 85% of the preset value, the buzzer will start to alarm. In preset value mode, force value will be stored in the highest state, when need to save data, you can press “M” key lightly to save data, when force value is zero, data is zero can be saved.

Tip: The buzzer will only respond when the buzzer function is on.

- Peak mode

In peak mode, LCD display shows maximum value of load torque, when need to save maximum data, you can press “M” key to save current maximum data or press “P/C” key ” to clear the current peak data.

③Torque unit conversion

Long press “M” key to enter menu program, lightly press “M” key to switch to UNIT option, then lightly press “△” key to freely choose 4 torque units, finally press Press the “M” key to save the selected torque unit and Exit the menu program.

④LCD Backlight Function

Long press the “M” key to enter the menu program, lightly press the “M” key to switch to LTON option, then lightly press the “△” key to choose to turn on or off the backlight. Number 1 means backlight is on and number 0 means backlight is off.

⑤ Store, view and delete data

In the peak mode, the product stores the force value data manually and presses the “M” key to save the current maximum torque. Long press the “M” key to enter the menu program, then lightly press the “M” key to find the data group, then lightly press the “△” key to view all the data. When need to delete saved data, press “M” key to switch to JELA option, then press “△” key to delete all saved data. Number 1 means clear data, number 0 means do not delete data, finally press “M” key to exit the menu program.

⑥ Set the buzzer

Press and hold the “M” key to enter the menu program, lightly press the “M” key to switch to the BUZZ option, and then lightly press the “△” key to select the buzzer on or off. Number 1 means on, number 0 means off, finally press “M” key to exit the menu program.

⑦ Low power consumption setting

Low power consumption can reduce battery power consumption and increase torque driver usage time. Press and hold “M” key to enter menu program, then lightly press “M” key to switch to LPOW option, and then lightly press “△” key to select on or off. Number 1 means on, number 0 means off, finally press “M” key to exit the menu program.

⑧ Restore factory settings

When setting confusing user data, you can restore factory settings and all parameters of the torque driver will be restored to the parameters of the factory settings. Press and hold the “M” key to enter the menu program, then lightly press the “M” key to switch to the RSET option, then lightly press the “△” key to select whether to restore the factory settings. The number 1 means factory reset, the screwdriver will turn off automatically after selecting, the number 0 means no restore, you can lightly press the “M” key to exit the program menu.

Note: Put 2 AAA batteries into the battery box, please pay attention to the direction of the positive and negative poles.

4.2. Parameter setting diagram

① Settings menu

② Unit installation diagram

③ Working mode setting diagram

④ Diagram of viewing and clearing data

⑤ Low power consumption installation diagram

⑥ LCD backlight setting diagram

⑦ Diagram of the buzzer setup

⑧ Factory reset diagram

- Repair and maintenance

To ensure product accuracy, the product must be tested regularly to ensure normal use.

① Verification requirements:

Define the verification interval according to the frequency of product use.

② Verification cycle:

Verification cycle is usually 12 months and verification cycle for frequently used products is 6 months, bolts and nuts mounted in critical locations must be verified before each use to ensure their accuracy.

③ Qualification:

Verifiers are manufacturers or qualified metrologists, and verification devices are verification tools with a systematic error of 0.3% or less.

④ Do not use it as a hammer during use and try to avoid bumps and falls.

⑤ It is strictly forbidden to use with 20% overload so as not to damage the sensor of the product.

⑥ It is strictly forbidden to disassemble the product arbitrarily, if you have any problems, please contact our company in time.

⑦ Put the product in the box after use.

- Accessories included

| seri | name | Quantity |

| 1 | Digital Torque Driver | 1 |

| 2 | Instruction book | 1 copy |

| 3 | Certificate/Warranty Card | 1 copy |

| 4 | desiccant | 1 package |

| 5 | 7 dry battery | 2 knots |

| 6 | Screwdriver | 1 piece |

Reviews

There are no reviews yet.